Thermal parameters

Max. Permissible Ambient Temperature : +90°C (stationary and in motion )

Max. Permissible Operating Temperature of The Conductor :

+120°C, Interpretation according to IEC 60216 : permanent temperature.

120°C for 20,000 h ( = 2.3 years ), at max. 90°C permanent temperature ( = 30 years ).

Short – Circuit Temperature : +250°C referring to a period of 5 sec.

Damp – Heat Test : According to EN 60068 – 2 – 78. 1,000h at 90°C and 85% humidity. Min. Permissible Ambient Temperature : -40°C (stationary and in motion) Resistance to Cold :

Bending test at low temperature according to DIN EN 60811 – 1 – 4, Impact test similar to DIN EN 50305.

Minimum Bending Radius : Fixed Installation approx. 4 x cable Ø

Electrical Parameters

Voltage Rating : AC 0.6 / 1.0 kV

Max. PV – System Voltage : DC up to 2.0 kV possible

Max. Permissible Operating Voltage in AC Systems : 0.7 / 1.2 kV Max. Permissible Operating Voltage in DC Systems : 0.9 / 1.8 kV Test Voltage : AC 6.5 kV / DC 15 kV (15 min.)

Mechanical Parameters

Tensile Load :15 N / mm² in operation. 50 N/mm² during installation

Shrinkage Test : According to EN 60811 – 1 – 3

Shore-Hardness : 85 shore A according to DIN EN 53505

Pressure Test at High Temperature : According to EN 60811 – 3 – 1

Dynamic Penetration Test : According to requirements for cables for PV systems, DKE / VDE 411.2.3

Chemical Parameters

Mineral Oil Resistance : 24h, 100°C according to DIN VDE 0473 – 811 – 2 – 1, DIN EN 60811-2-1

Acid and Alkaline Resistance : According to EN 60811-2-1

7 days, 23°C (N-Oxalic Acid, N-Sodium Hydroxide)

Ammonia Resistance : 30 days in saturated ammonia atmosphere (internal testing)

Weather Resistance : Ozone resistance according to DIN EN 50396 test Type B, HD 22.2 test Type B UV – resistance according to UL 1581

(Xenon – Test), ISO 4892 – 2 (Method A) and HD 506/A1-2.4.20

Absorption of water (gravimetric) according to DIN VDE 0473-811-1-3, DIN EN 60811 – 1 – 3.

Behavior in Case of Fire :

Flame propagation.

Single cable according to DIN VDE 0482 Part 332 – 1 – 2, DIN EN 60332 – 1 – 2.

Multiple cable according to DIN VDE 0482 Part 266 – 2 – 5, DIN EN 50305 – 9.

Low smoke emission according to DIN VDE 0482 Part 268 – 2.

DIN EN 50268-2 (light transmittance > 70% ).

Corrosivity according to DIN EN 50267 – 2 – 2.

Toxicity according to DIN EN 50305, ITC – index < 3.

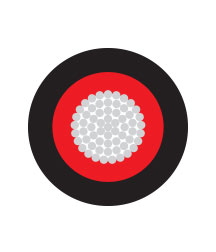

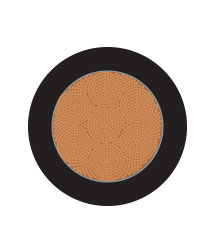

Cable Construction

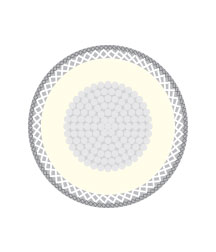

Conductor : Fine Wire Tinned Copper Conductor according to BS EN 60228:2005 cl. 5.

Insulation : UV resistant, cross linkable, halogen free, flame retardant compound for core insulation.

Core Identification : Red, black or natural

Sheath : UV resistant, cross linkable, halogen free, flame retardant compound for Sheath over insulation.

Cable Colour : Red, Black, Black with Red Strip

Please complete the part numbers for these cables by adding the suffix (in place of “xx”) for the insulation colour required as per the list: 02 – black, 03 – red, 13 – natural